- THE CRAFTSMANSHIP -

WELCOME INTO OUR FACTORY

Since 1964, our brand has had the privilege of operating our own factory. This gives us the unique opportunity to closely manage and influence the entire production process. While local manufacturing has become increasingly rare in the textile industry, we continue to invest in it — that makes our brand stand out.

We work with original machinery, some of which is one-of-a-kind in the market. We’re proud of this heritage, not as a point of prestige, but as a way to honor the craftsmanship that defines our products.

Our goal is to elevate traditional techniques into something both luxurious and meaningful. Many of our team members have decades of experience working with linen wallcoverings, and they bring deep knowledge and genuine passion to every step of production.

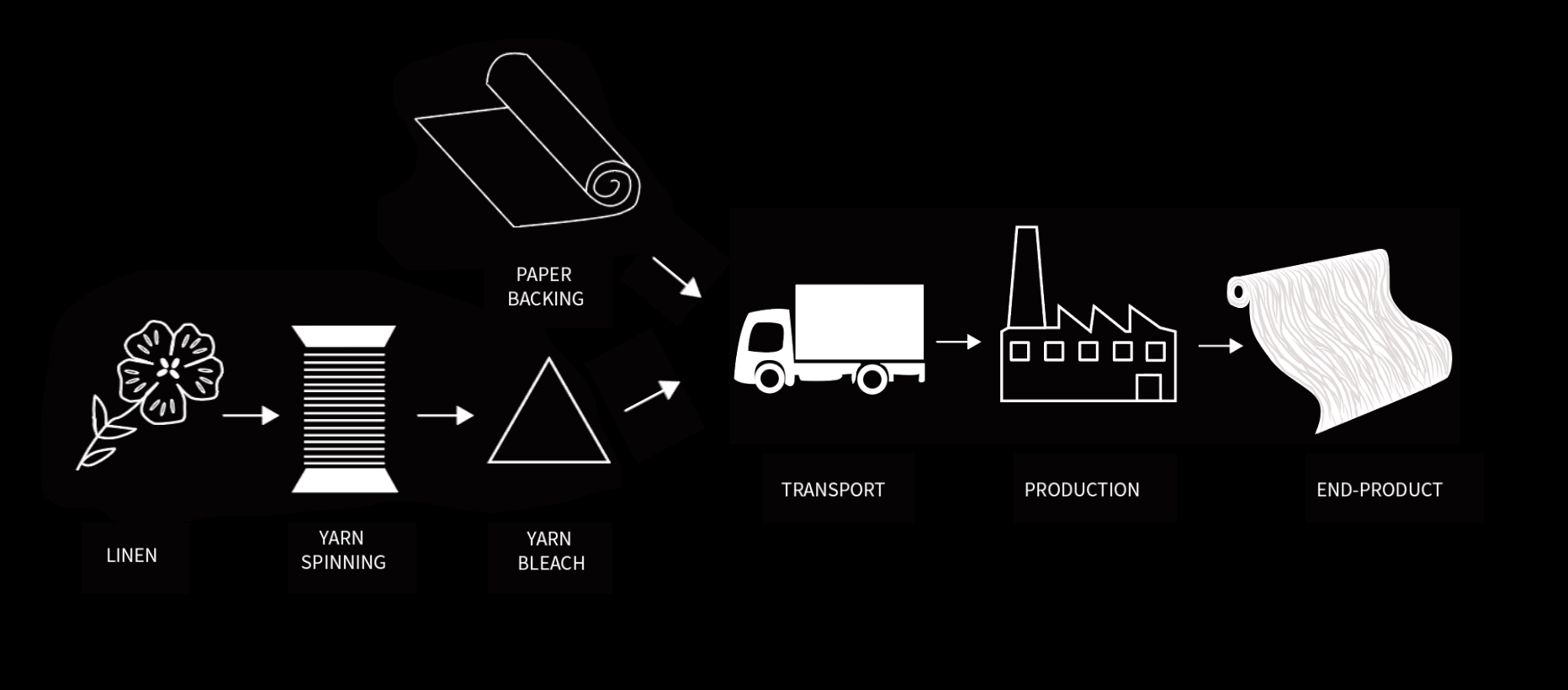

The process of creating our wallcoverings — from combining linen yarn with paper, to the finishing touches — involves several carefully considered steps. We’ve made deliberate choices when it comes to materials and suppliers to ensure the highest quality in the final product.

In the section on our supply chain, we outline the journey from raw fiber to finished wallcovering. Our aim is to provide you with a deeper understanding of our production process and to be as transparent as possible about how we work.

We’re also aware that no production is entirely without environmental impact. Still, we believe strongly that responsible decisions — at every stage — can lead to meaningful improvements.

NOVALIN SUPPLY CHAIN

THE SUPPLY CHAIN

The product’s lifecycle begins with natural materials — linen fiber from flax flowers and paper backing sourced from trees.

There are many steps before it becomes the finished wallcovering you see on your wall. In this section, we’ll guide you through that journey, sharing the story behind the product as clearly and informatively as we can.

Linen (flax) – Today, flax is regarded as an exclusive textile material and is produced in relatively small quantities. Linen is available in both long and short staple lengths. It is the strongest of all vegetable fibers, possessing two to three times the strength of cotton. To preserve the full length of the flax fibers, the plant must be pulled from the ground rather than cut.

Our wallcoverings are made from yarn spun using 100% linen, sourced from flax grown in the south of Holland, Belgium, and the north of France—no more than 150 km from the sea. The climate in these regions provides ideal conditions for cultivating high-quality flax fibers.

Yarn Spinning – The yarn is spun by flax spinners in Poland. Linen is one of the few natural fibers that becomes stronger when wet. The spinning process used is either semi-wet or full-wet spinning to produce smoother linen yarns. Novalin works exclusively with long fiber yarns, which provide greater stability and reduce the ‘hairy’ effect in the finished product.

We use two different types of yarn in our collections. The 97 Robust collection features a thicker, more textured yarn compared to the yarn used in 95 Classic and 20 Sveagarden.

Yarn Bleaching – The yarn is delivered raw to our long-time partner in Kinna, Sweden, to create true white linen. The natural color of linen fibers is, at best harvest, yellowish, and to achieve the best colors in the final product, the yarn must first be bleached white. Bleaching also slightly softens the stiff fibers, making them more pliable. However, over-bleaching can weaken the fibers, so the process must be carefully controlled.

Paperbacking – Our paper backing is a specially developed crêpe paper that prevents shrinking. We work with a supplier in Germany who helps us produce this type of paper for our unique wallcoverings. The paper is FSC-certified by the Forest Stewardship Council (FSC), ensuring that the forestry practices used are environmentally responsible and sustainable.

Transport – We use trucks to transport our materials from our suppliers. We keep the carbon footprint as low as possible and maintain the highest quality standards by sourcing everything within the EU. We also aim to reduce unnecessary shipments by placing fewer, but larger, orders, thereby minimizing environmental impact.

Production – After the yarn is carefully spun and bleached, and premium paper arrives at our factory in Kinna, the journey of creating our wallcoverings begins.

First, the linen yarn is expertly warped onto beams—each production run requires between 3 and 8 warp beams, depending on the design. Our skilled team then mixes colors in-house to achieve the perfect tones, ensuring every shade is tailored to our collection.

In a seamless process, our production machine applies the color and assembles the wallcovering, bonding the linen yarn to its durable paper backing. Once a continuous roll is complete, the material is precisely cut and packaged into convenient 10,05 and 50-meter rolls, ready to transform interiors with timeless texture and character.

End-Product -The final product is a linen wallcovering available in three different designs and a wide range of color shades. (Find our collections here.) We primarily sell to resellers across Sweden and internationally.

Our linen wallcoverings are known for their durability—some have remained on walls for over 30 years—thanks to their high quality and timeless design. While the product is not reusable, its longevity reduces the need for frequent replacements, thereby lowering its overall environmental impact. Additionally, since it is made from natural materials, it decomposes more easily at the end of its lifecycle.

Certificates – Our factory and products are certified according to ISO 14001, the international standard for environmental management systems. We have maintained this certification over time, which we are very proud of.

Our environmental COMMITMENT

At the heart of our work lies a simple principle: minimize impact, maximize quality. Sustainability is not an afterthought for us—it begins at the very first step of our supply chain. By making conscious choices early, we ensure that responsibility is built into every stage of production.

We are selective in our choice of partners. All our suppliers are based in Europe, which helps us reduce transportation distances and emissions, while usually providing better traceability and standards.

Our philosophy is clear: produce less, but better. We believe durability is the ultimate form of sustainability. That’s why we work exclusively with yarn spun from 100% pure linen—the finest, most luxurious fiber available. It’s a costly choice, but one that ensures our wallcoverings are not just beautiful, but made to last for decades.

We acknowledge that circular economy principles don’t always align with products like ours, which are not easily reusable. Instead, we proudly embrace a timeless approach: craftsmanship that endures. Where others offer fast, disposable production, we deliver quality that holds its value over time.

We also know sustainability is a journey. One of our key priorities is to reduce overproduction by moving toward a made-to-order model, aligning what we create more closely with real demand. Every decision brings us closer to a future where less waste, more care, and enduring craftsmanship define our industry.